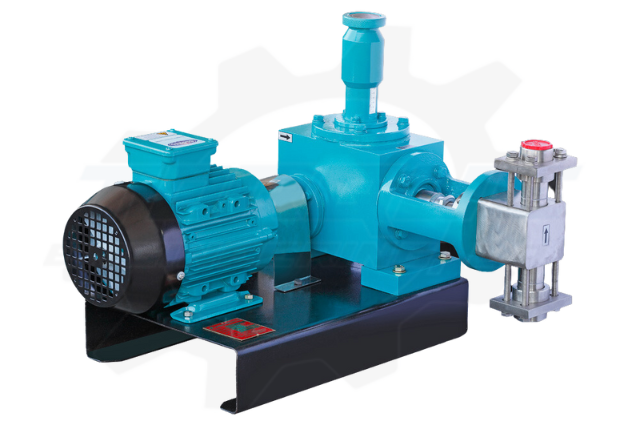

Dosing Pumps

Characteristics and Design Features

Dosing Pumps are solenoid-operated diaphragm type Dosing Pumps best fitted to chemical dosing into water & wastewater treatment (RO) applications. The typical use of those pumps is for chlorine, PAC, Alum, Anti-scale, Boiler chemicals dosing, etc. The standard & reliability of dosing pumps are certified and endorsed by thousands of users thus far.

Features

- Easy installation

- Available in multi-head

- Dimensional accuracy

Materials

- AISI 304, AISI 316

- Alloy 20, Hast Alloy B, Hast Alloy C

- Polypropylene, Teflon, Titanium

Parts of a Chemical Dosing System

- Chemical Container or Tank Holds the merchandise to be dosed.

- Pump Varies in materials and size, includes an inlet, suction line, and dosing line.

- Injector One-way valve where the chemical is injected into the product; overcomes pressure within the pipe and allows chemical into liquid flow.

- Foot Valve One-way valve attached to the suction line; placed into the product drum and keeps the pump primed.

- Dosing Line Rigid tube or reinforced hose; are often PE, PVC, or chrome steel for high-pressure use.

- Control System Ensures accuracy, activates and off at specific times. are often an easy flow switch or timer, up to a SCADA central system for various sensors, and therefore the ability to integrate into a bigger system.